ACCURATE, MATERIAL LED ANALYSIS

Our systems model the behaviour of your chosen polymer with high precision, using detailed material data to replicate real moulding conditions. This allows us to predict issues such as shrinkage, sinks, voids or cosmetic defects long before tooling begins, helping you make better design and material decisions early in the process.

ENGINEERING SUPPORT FROM THE START

Successful moulding begins long before a tool is cut. By analysing your part design early on, we can understand how the material will flow, fill and cool inside the mould. This lets us identify challenges such as poor filling, trapped air or weak knit lines, allowing improvements to be made before tooling progresses, saving time, cost and reducing risk.

REFINING EXISTING COMPONENTS

When an existing part is not performing as it should, our simulation and design tools help reveal what is happening inside the mould during each cycle. This gives us a clear basis for recommending targeted process adjustments or minor tooling refinements, restoring stability and improving quality without unnecessary downtime.

Twyco supports a wide range of CAD formats, including STEP, Parasolid, IGES, DXF, DWG and PDF. Whether you are developing a brand new part or seeking to improve a current one, we deliver the engineering insight needed to achieve a reliable, production ready design.

_edited_edited.jpg)

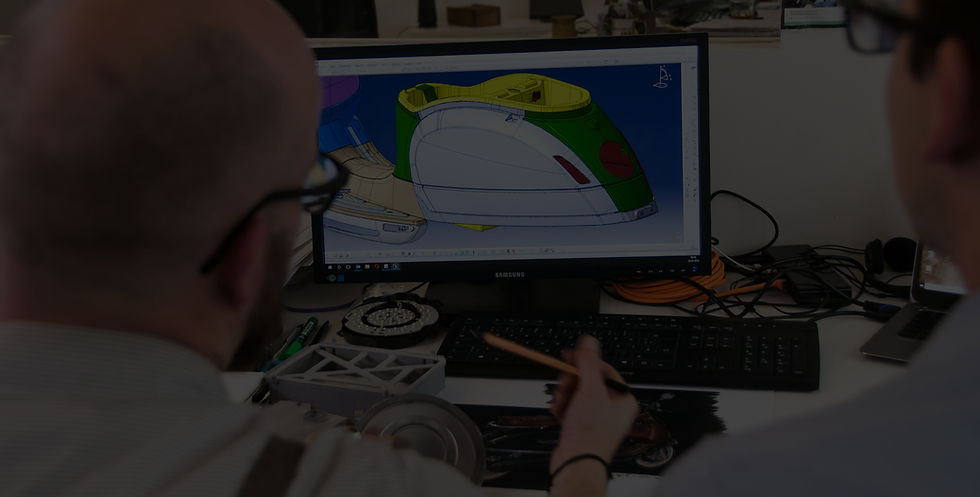

Design For Manufacture

We support design-for-manufacture (DFM) from the earliest concept, developing production-ready designs optimised for geometry, material selection, manufacturability, and cost.

By combining practical engineering expertise with real-world production knowledge, we deliver reliable, efficient components built for repeatable manufacturing and long-term performance.

Active tools to over 180 global customers

Produced every year for our customers

Injection moulding machines available

Designing Smarter For Injection Moulding

Designing for plastics requires careful consideration of geometry, flow, tooling and long-term performance which is why our specialists are here to guide you from the start.

Using advanced mould-flow simulation, we fine-tune every new mould design to ensure optimal material flow, efficient cooling, and robust part quality. This approach delivers reliable, cost-effective designs from day one and helps eliminate issues long before production begins.

End-to-End Project Ownership

We handle everything from design to delivery.

Technical Expertise

Decades of experience in materials and tooling

True Partnership Approach

Transparent, proactive, and long-term support

Design Support To Save You Time & Money

Instead of relying on costly external design services, Twyco works with you from the very first idea through to a fully optimised, mould-ready component. Using advanced 3D CAD and mould-flow analysis, we guide every stage of the injection moulding design process, ensuring your part is engineered for performance, manufacturability and value.

Throughout development, we share our expertise to refine material choices, geometry, production efficiency and overall cost. By involving us early, you significantly reduce project risk and avoid expensive design changes later on helping you bring a better product to market, faster and more efficiently.