Plastic Injection Part Assemblies

We specialise in the assembly of injection-moulded plastic parts, offering full or partial assemblies that reduce your production steps and ensure perfect component fit. Our services include ultrasonic welding, gluing, mechanical fastening, and multi-material assembly, all performed with strict quality control to guarantee consistency and performance.

Our assembly operations encompass ultrasonic welding, mechanical fastening, gluing, and multi-material joining, supported by rigorous quality checks and fixture control. With scalable production lines and flexible logistics, we can supply fully finished assemblies directly to your production flow reducing handling, streamlining supply chains, and improving overall efficiency.

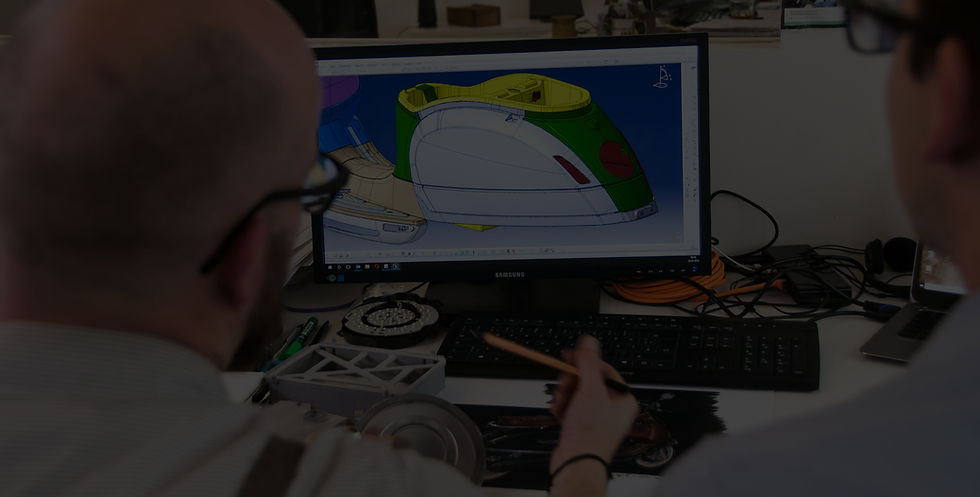

Your Vision, Our Expertise

We bring your ideas to life through a deep understanding of materials, manufacturing and precision moulding. Our experience spans a wide variety of polymers, from prime and reprocessed plastics to glass and mineral filled compounds, enhanced with advanced additives such as flame retardants, antimicrobials and blowing agents. We also specialise in insert and outsert moulding, offering complete versatility for complex component design.

Backed by a fully integrated ERP system, we provide total traceability and production flexibility. Whether you need made to order parts or ongoing scheduled supply, we can produce in bulk and hold stock for convenient call off, ensuring consistent quality, reliability and cost efficiency.

End-to-End Project Ownership

We handle everything from design to delivery.

Technical Expertise

Decades of experience in materials and tooling

True Partnership Approach

Transparent, proactive, and long-term support

Large Injection Mouldings

Save both time and cost through efficient production and smart design support.

We specialise in large-scale injection moulding, producing complex, high-strength parts that demand precision, functionality, and aesthetic quality. Our extensive experience in handling large components ensures consistent results whether for structural panels, housings, or industrial assemblies.

We also have particular expertise in thick-section moulding, where precise control of material flow and cooling is essential to maintain dimensional accuracy and strength.

To complement production, we provide a complete suite of value-added services, including large-part assembly, finishing, and secondary operations, ensuring every project is delivered ready for end use.

_edited_edited.jpg)

UK Plastic Injection Moulding for Precision and Performance

Advanced plastic injection moulding backed by decades of expertise, producing cost-effective, high-quality components for OEMs and brand owners.

Our UK facility supports small precision parts to large, heavy-duty components, with clamp forces up to 1,700 tonnes. Every project benefits from DFM, tooling, and process optimisation to ensure consistent quality and reliable production.

Active tools to over 180 global customers

Produced every year for our customers

Injection moulding machines available