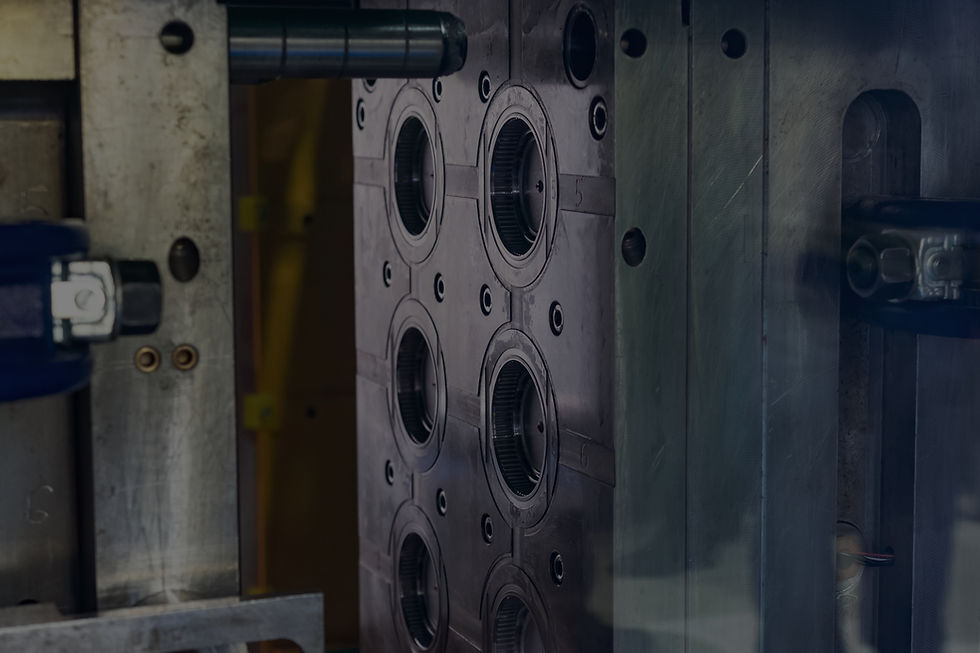

Existing Moulds

Looking for a partner to support and maintain your existing tooling? We can take your current moulds, adapt them to run seamlessly on our machines, and carry out any necessary adjustments or optimisation. To help you evaluate performance, we’ll also produce sample mouldings free of charge.

_edited_edited.jpg)

Injection Mould Tool

We design and manage high-precision injection mould tooling engineered for performance, durability, and cost control, delivering consistent quality from first shot to full-scale production.

From prototype and pre-production tools to multi-cavity and multi-material moulds, every tool is optimised for cycle time, reliability, and ease of maintenance reducing downtime and protecting long-term production value.

World Class Tooling, Built for Performance

At Twyco, we know exceptional moulded parts depend on exceptional tooling. Every mould we supply is engineered for accuracy, reliability and long-term performance.

With UK engineering control and trusted tooling partners in China, we combine premium European-grade steel with advanced machining to deliver high-precision tools at highly competitive prices.

Each Twyco tool is built to last, manufactured to tight tolerances and optimised for efficient production ensuring consistent, dependable results from the first shot onwards.

End-to-End Project Ownership

We handle everything from design to delivery.

Technical Expertise

Decades of experience in materials and tooling

True Partnership Approach

Transparent, proactive, and long-term support

What is Injection Moulding

Injection moulding is a highly efficient manufacturing process where molten plastic is injected into a precision-engineered mould to form a specific shape. Once cooled, the part is ejected and ready for use allowing fast, repeatable, and cost-effective production.

This method offers exceptional design flexibility, tight tolerances, and the ability to scale quickly from prototypes to millions of parts. Its reliability and versatility make injection moulding the go-to choice across sectors including automotive, consumer products, medical, electronics, industrial equipment, and more.

Active tools to over 180 global customers

Produced every year for our customers

Injection moulding machines available

Routine Tool Maintenance

Routine tool maintenance is provided free of charge for any injection mould we manufacture or supply through our trusted partners, for as long as Twyco remains your appointed moulder. This ensures your tooling continues to perform at its best throughout its entire working life. You can be confident that your investment is protected, your production remains stable, and downtime is kept to an absolute minimum.