Services

Injection Moulding

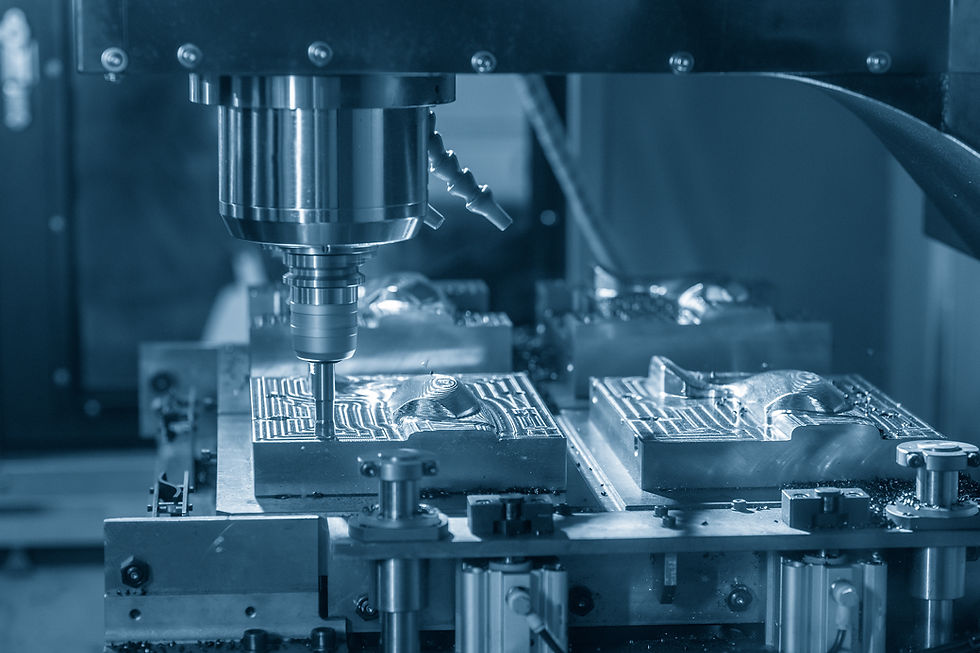

Twyco's plastic injection moulding process produces bespoke production ready parts. We manufacture steel moulds with scope for modification if necessary (post initial sample review) and offering a low-cost mass production tool.

What is Injection Moulding

Plastic injection moulding is the process of melting plastic pellets (Thermosetting/Thermoplastic polymers) that when malleable, can be injected at pressure into the mould cavities, filling and solidifying producing the final product.

Why would you choose Injection Moulding for your Project

Injection moulding is a precise and consistent method that can manufacture almost any type of plastic part. This is one of the most commonly used technologies in the plastic manufacturing industry it is also one of the fastest methods dependant on the complexity of the mould, with cycles of production lasting between 15 and 30 seconds.

Injection moulding machines tend to work automatically, keeping operational costs down leading to a cost-effective end product.